Siemens Centre of Excellence

(A Hub for Innovation and Skill Development)

The Siemens Centre of Excellence is a state-of-the-art facility dedicated to fostering innovation and skill development in various engineering disciplines. Equipped with a diverse range of cutting-edge laboratories, the Centre offers a comprehensive learning environment for students, researchers, and industry professionals.

Key Laboratories:

Product Design & Validation Lab:

- Enables students and researchers to model, analyse and validate complex products using advanced CAD software.

- Facilitates rapid prototyping and iterative design processes.

- Provides access to industry-standard design tools and methodologies.

Advanced Manufacturing Lab:

- Houses state-of-the-art manufacturing equipment, including 3D printers, CNC machines, and robotic arms.

- Enables hands-on experience in additive manufacturing, subtractive manufacturing and automation technologies with exposure to advanced CAM software.

- Promotes experimentation and innovation in manufacturing processes.

Test& Optimization Workshop and Lab:

- Equipped with advanced testing instruments and software for condition monitoring and performance evaluation.

- Supports research and development activities in materials science, engineering mechanics and product optimization.

- Provides opportunities for students to conduct experiments and analyse results.

CNC Programming & Machining Lab:

- Offers hands-on training in CNC programming and machining techniques.

- Provides access to high-precision Turning Centre and Machining Centre for manufacturing complex and accurate components.

- Encourages students to develop skills in computer-aided manufacturing and digital fabrication.

Rapid Prototyping Lab:

- Enables rapid prototyping of designs, accelerating product development cycles.

- Fosters innovation and experimentation

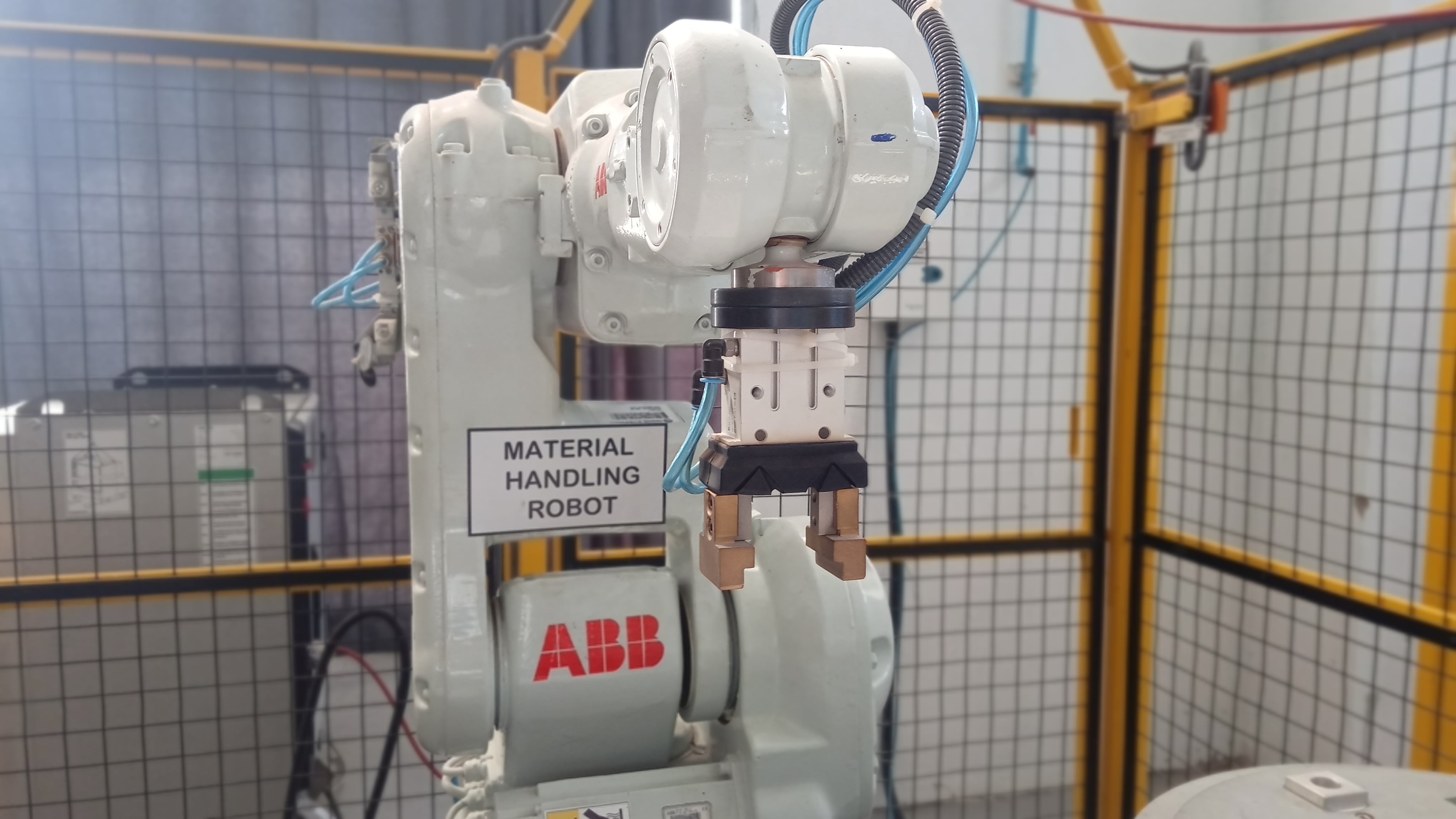

Robotics Lab:

- Houses a variety of industrial and educational robots for training and research purposes.

- Enables students to learn about robotics programming, control systems and automation solutions.

- Fosters innovation in robotics applications, including automation, manufacturing and healthcare.

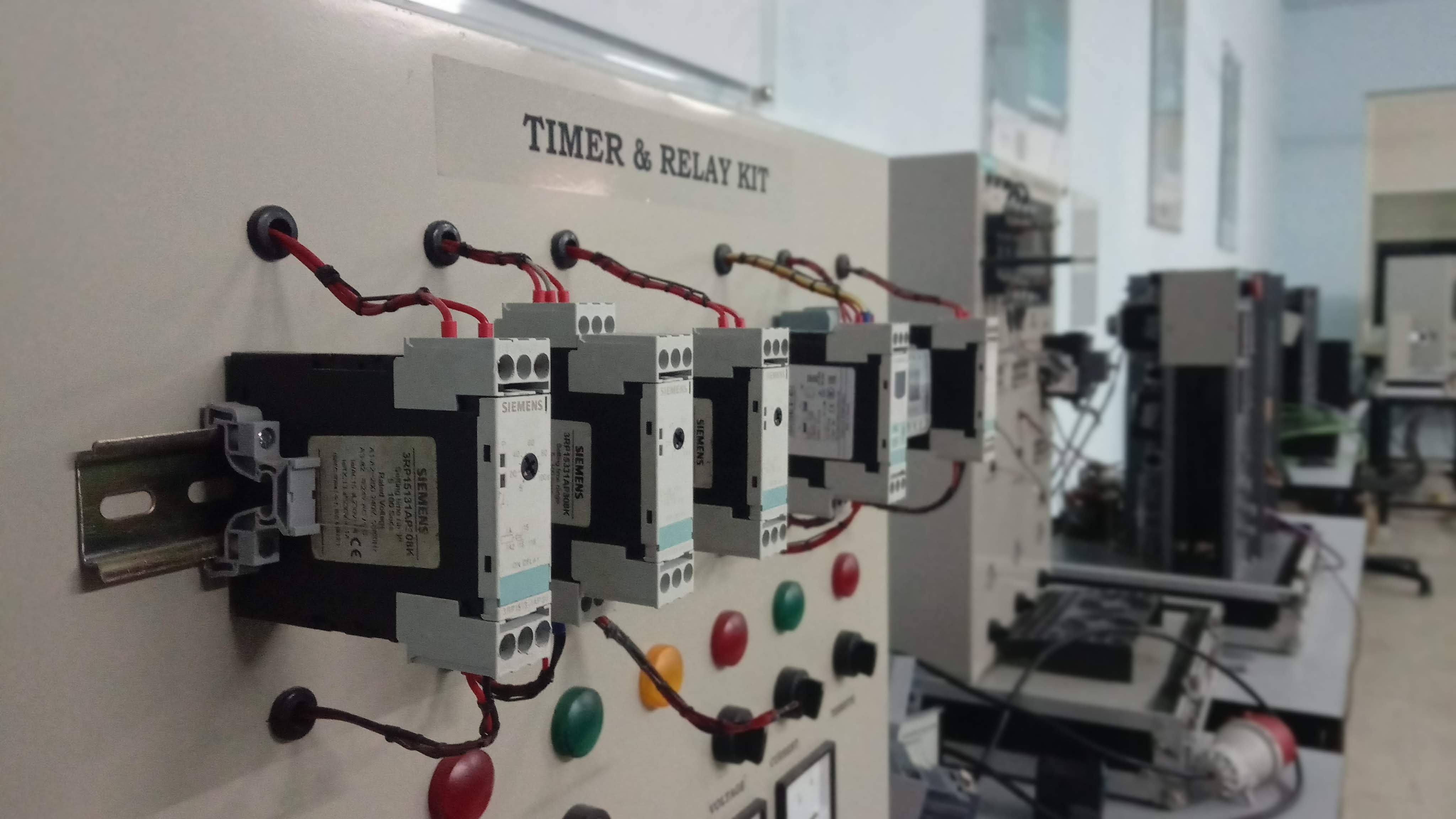

Electrical and Energy Studies Lab:

- Provides a platform for studying electrical power systems, power electronics, and renewable energy technologies.

- Equipped with advanced simulation tools and hardware setups for analysing power system behaviour and designing energy-efficient solutions.

- Supports research in areas like power quality, grid integration, and energy storage.

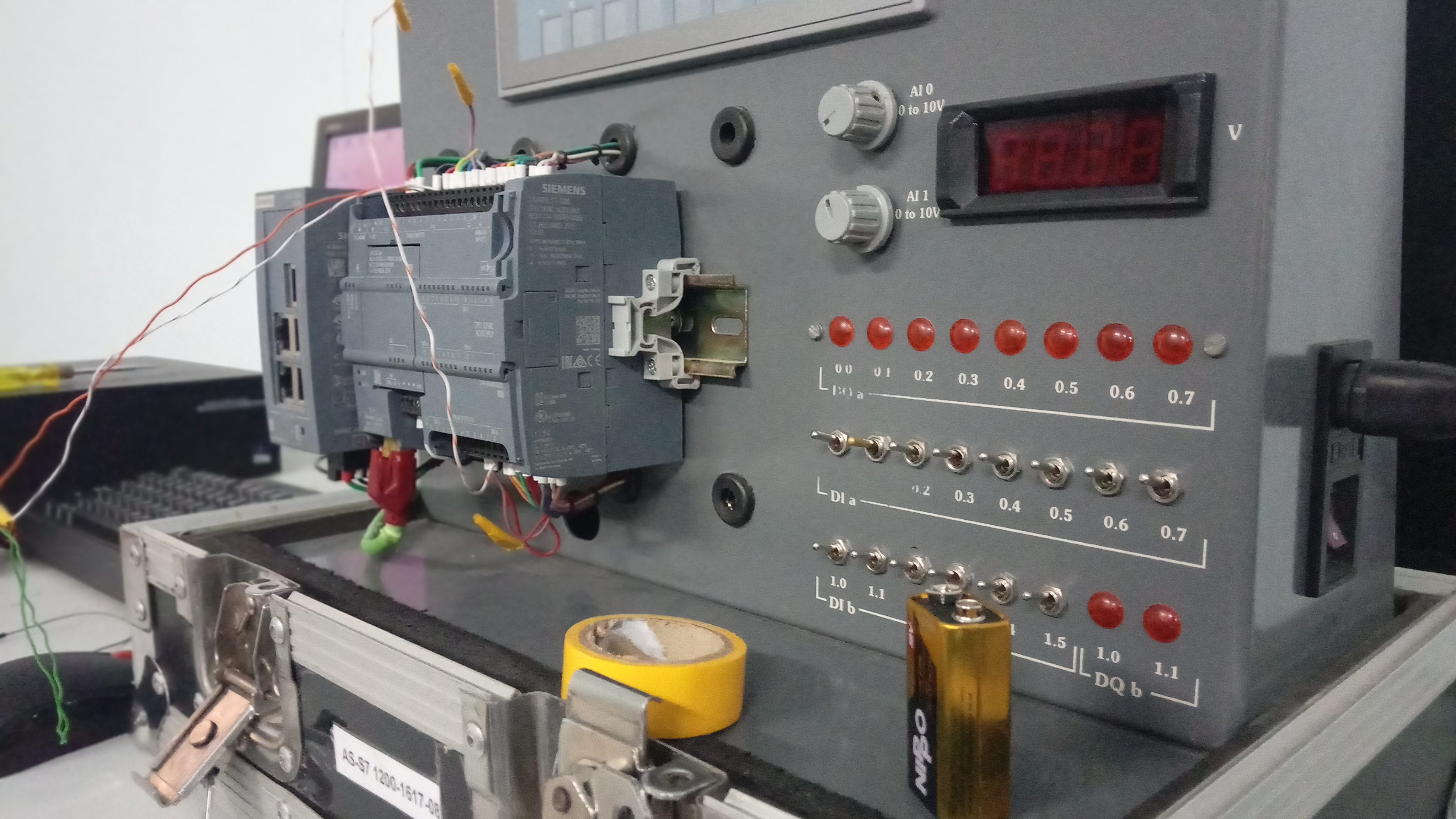

Automation Lab:

- Focuses on industrial automation and control systems, including programmable logic controllers (PLCs), SCADA systems and human-machine interfaces (HMIs).

- Enables students to gain practical experience in designing, implementing, and troubleshooting automation solutions.

- Promotes interdisciplinary learning and collaboration between various engineering disciplines.

Mechatronics Lab:

- Combines mechanical, electrical and electronics engineering principles to develop integrated systems.

- Provides hands-on experience in designing and building mechatronic systems, such as automated assembly lines, robotic arms, autonomous vehicles and smart devices.

- Encourages innovation in emerging fields like IoT, robotics and artificial intelligence.

Process Instrumentation Lab:

- Focuses on the measurement, control and automation of industrial processes.

- Equipped with a variety of sensors, transmitters, receivers and control valves for process monitoring and control.

- Provides opportunities for students to learn about process control strategies, calibration of instruments and data acquisition systems.

Automobile Body Repair and Body Paint Lab:

- Offers practical training in automotive body repair and body paint techniques.

- Provides access to industry-standard tools and equipment for diagnosing and repairing automotive systems.

- Encourages students to develop skills in automotive painting technologies and body repair technologies.

The Siemens Centre of Excellence plays a crucial role in bridging the gap between industry and academia by providing students with the necessary skills and knowledge to excel in the modern engineering industry. By fostering innovation, collaboration and practical learning experiences, the Siemens Centre of Excellence empowers students to become future leaders in engineering and technology.